Our Business

Customer Witness

Our Business

Customer Witness

Media Center

Latest information at the first time!

In which fields should it be applied?

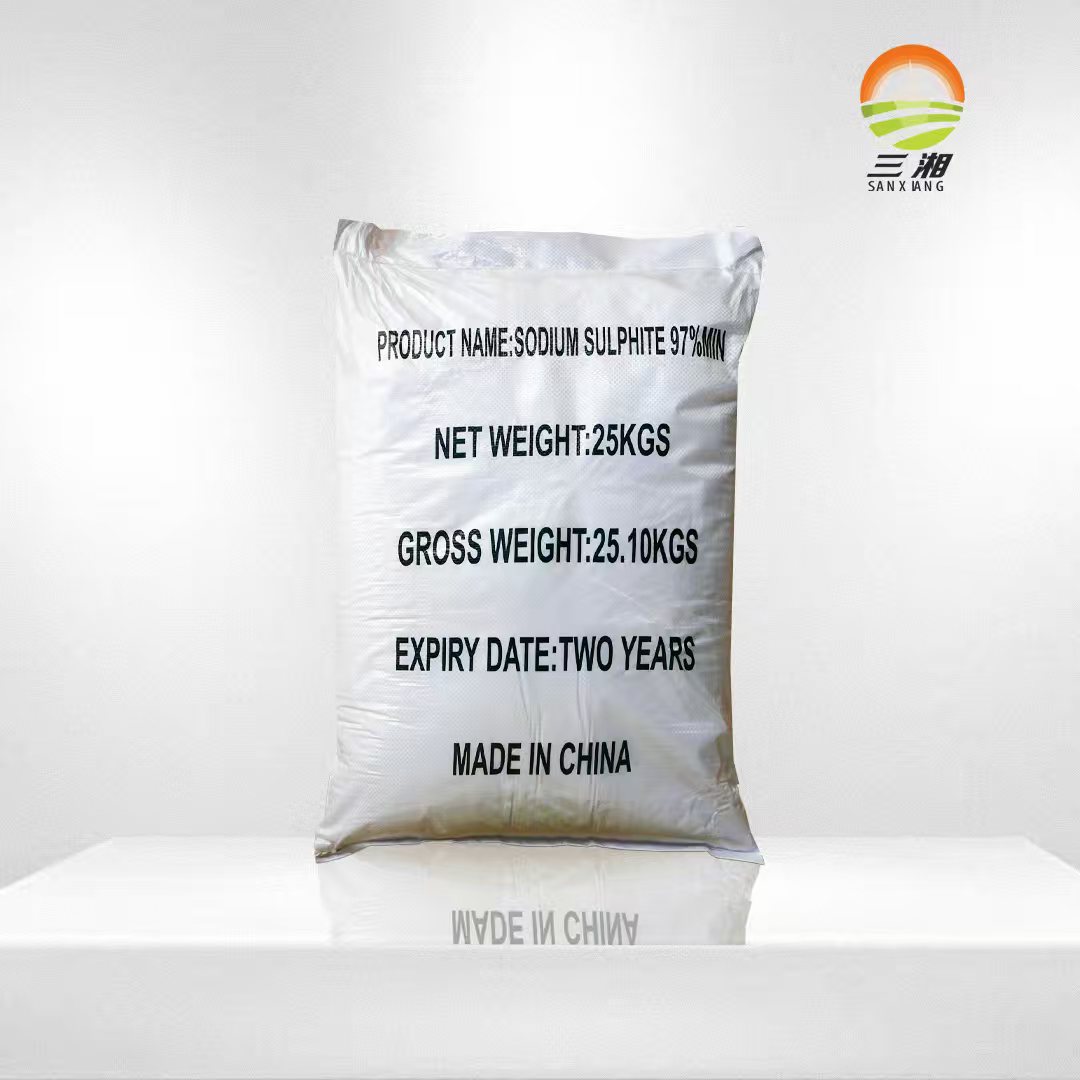

Recently, the sodium sulfite series products of Hunan Yueyang Sanxiang Chemical Co., Ltd. have continuously secured orders in domestic and international markets by virtue of their stable and excellent performance, diversified application scenarios and green production advantages. These products have won high recognition from customers in food, pharmaceutical, printing and dyeing and other industries, becoming an important growth engine for the high-quality development of the enterprise. As a seasoned enterprise deeply engaged in the inorganic salt chemical industry, Sanxiang Chemical takes technological innovation as the core and quality control as the cornerstone, enabling its sodium sulfite products to stand out in market competition and inject strong impetus into the development of various industries.

A "Fresh-keeping Guardian" in the Food Field, Strictly Adhering to the Safety Bottom Line

In the food industry, food-grade sodium sulfite is widely used in the processing of preserved fruits, glucose, liquid glucose, edible sugar, bamboo shoots, mushrooms, canned food, grape concentrate and other products due to its efficient antiseptic, antioxidant and bleaching properties. It can effectively inhibit the growth of microorganisms, prevent food spoilage, maintain the stability of food color and flavor, and can also be used as a decolorizing agent to improve food appearance. The residual amount is strictly controlled within the national standard range to ensure food safety.

A "Practical Assistant" in Industrial Production, Solving Practical Problems

In the industrial field, sodium sulfite plays an irreplaceable role, especially in textile printing and dyeing, water treatment and other industries, becoming a practical assistant to solve production problems.

On the production lines of textile printing and dyeing factories, white cotton cloth needs to be bleached before dyeing. In the past, the use of traditional bleaching agents not only had complex processes, but also easily caused damage to cotton fibers, hardening of hand feel, and even uneven dyeing. The situation has been significantly improved after switching to industrial-grade sodium sulfite as a bleaching auxiliary. Using it to bleach cotton cloth can not only simplify the process steps, but also improve the whiteness of cotton cloth, make subsequent dyeing more uniform, maintain the soft hand feel of cotton cloth, and improve the qualified rate of products.

In urban sewage treatment plants, sodium sulfite is an important agent for treating residual chlorine. Waterworks add chlorine for disinfection before water supply. If part of the unreacted residual chlorine is directly discharged with sewage, it will cause harm to aquatic organisms in rivers. According to the residual chlorine content in sewage, sodium sulfite solution is accurately added, which can quickly react chemically with residual chlorine, reducing the residual chlorine content in sewage to below 0.05mg/L, fully complying with the national first-class standard. Compared with traditional treatment processes, using sodium sulfite to treat residual chlorine reduces costs by 30% and improves treatment efficiency by 40%.

Expanding Applications in High-end Fields, with Safe Operation as the Premise

With the continuous progress of technology, high-purity sodium sulfite has begun to enter high-end fields such as medicine and electronics. In the pharmaceutical industry, it is an important raw material for the production of cephalosporin antibiotics, vitamin C and other drugs, and participates in the drug synthesis process as a reducing agent to ensure the smooth progress of the reaction. In the electronic industry, specially purified sodium sulfite can be used in the cleaning process of semiconductor chips to remove residual metal impurities on the chip surface, providing a guarantee for the stable performance of chips.

It should be noted that sodium sulfite must be used and stored in strict accordance with safety specifications. Production enterprises should equip operators with professional protective equipment such as dust masks, acid and alkali resistant gloves, and protective glasses. Storage warehouses should be away from fire and heat sources, kept cool and ventilated, and strictly stored separately from oxidants, strong acids, edible chemicals, etc., to avoid safety accidents. As long as the operation is standardized, sodium sulfite can play a safe and efficient role in various fields.

From food preservation on the tip of the tongue, to process optimization in industrial production, and then to sewage treatment in the environmental protection field, sodium sulfite has proved its value through tangible applications. This seemingly ordinary chemical raw material is silently guarding every link of life quality and industrial development as an invisible helper.

Looking forward to the future, Sanxiang Chemical will take the construction of the new Linxiang factory as an opportunity to further expand the production capacity of sodium sulfite, continuously increase R&D investment, focus on emerging fields such as food additives and new power battery materials, and promote product iteration and upgrading. At the same time, the enterprise will continue to uphold the spirit of "Strictness, Pragmatism, Development and Innovation", and help the high-quality development of various industries with better products, more perfect services and greener production modes, writing a new chapter in the innovative development of sodium sulfite products.